So during the ongoing Human Malware situation we have been concentrating on imaging asteroids, comets and more recently performing exoplanet measurements on the 12inch RC than long exposure deep sky astrophotography.

Astronomy is one those hobbies that is for most part is sole activity for the dark early hours of the morning and these days is usually done remotely. It was therefore disappointing that when one of the team went to use the Sky-Watcher Esprit 120ED for a night of astrophotography and found that he was unable to open the Optec Alnitak Flip-Flat. As the lockdown and travel restrictions progressed due to the initial wave of the human malware situation the issue was soon forgotten as we continued our focus to performing exoplanet observations on the 12inch RC for the ESA Ariel Mission.

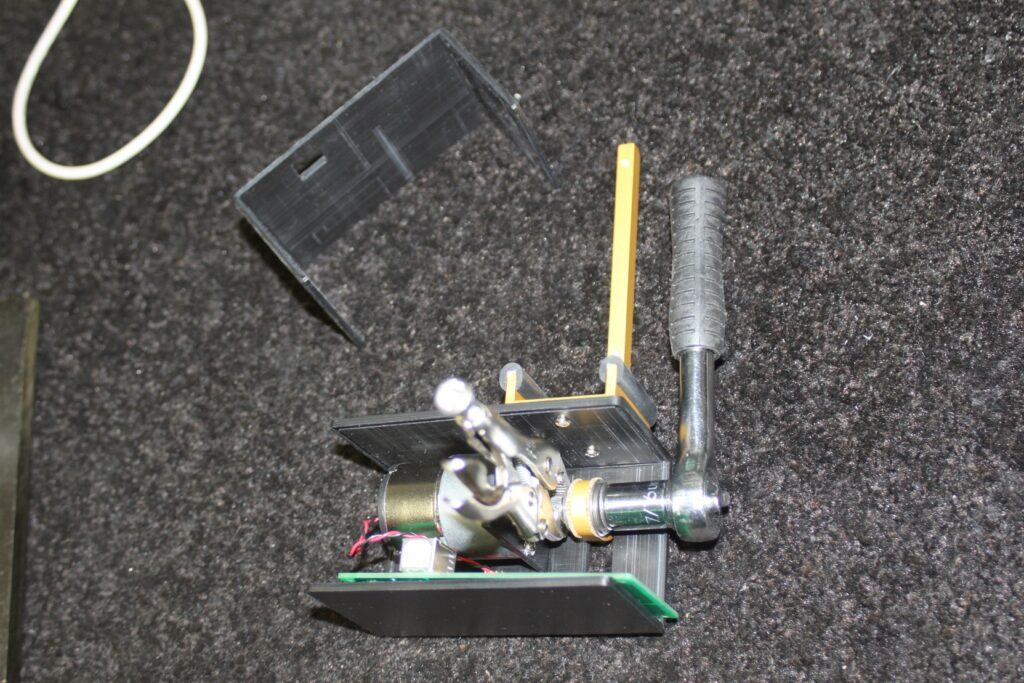

Now that IMT3 has been decommissioned ready for it to be reborn as IMT3b at it’s new rural darker sky site I decided to take the opportunity to retrieve the FlipFlat and diagnose the issue at home on my desk.

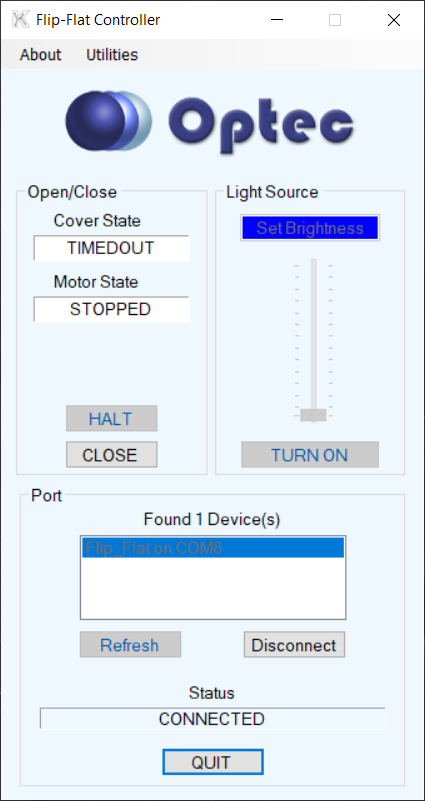

Using the Alnitak controller software, I could hear the motor running but it never seemed to complete the close or open. All it continued to display was the TIMEDOUT message as shown below.

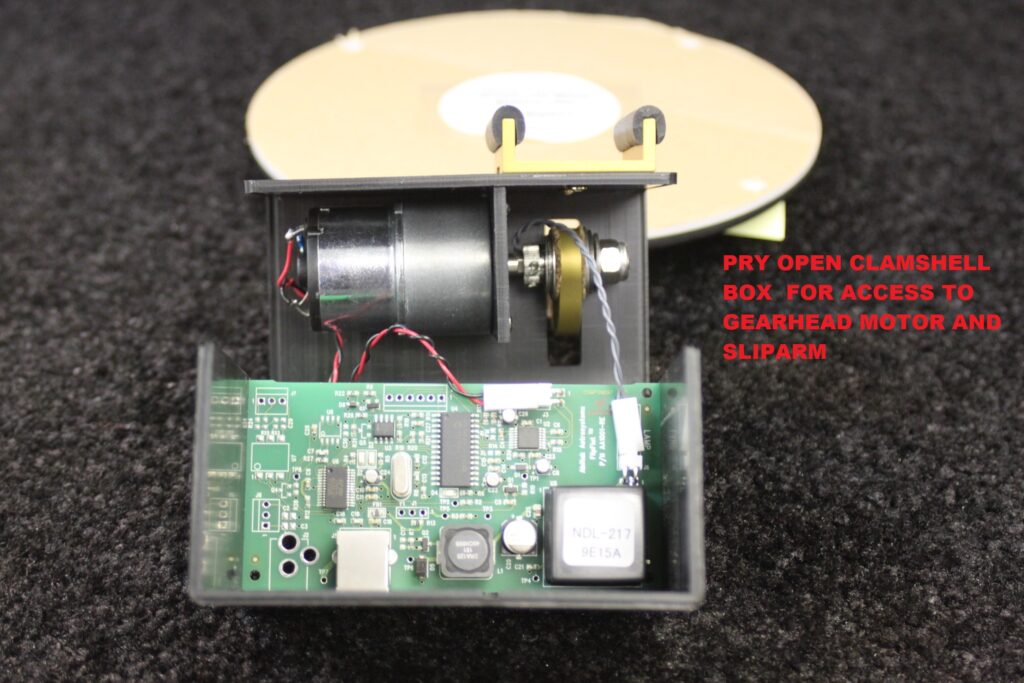

I sent an email off to the vendor I purchased it from but after a month I got no reply. In the hope I would not be left with an expensive paperweight I reached out to Optec. After quite a few weeks of getting no reply I was pleasantly surprised to receive a message from Jeff Dickerman (President) of Optec. Jeff apologised for not responding earlier and offered to help resolving the issue. The error message seemed to be a known issue and it was generally an easy resolution which required taking the box apart. Jeff sent me instructions on how to take the unit apart and fix the problem.

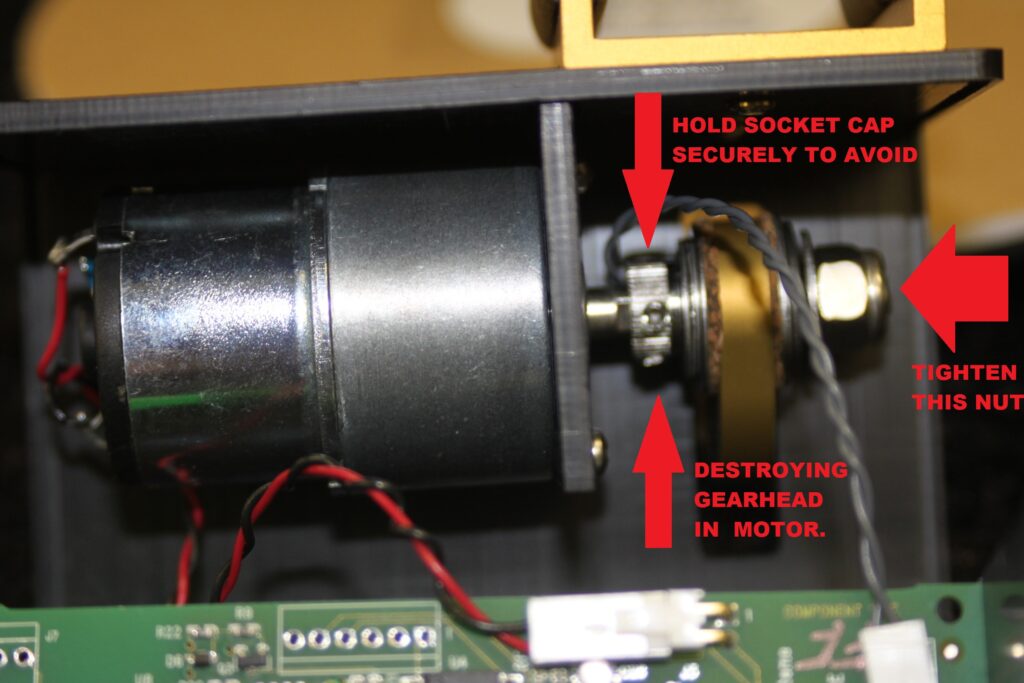

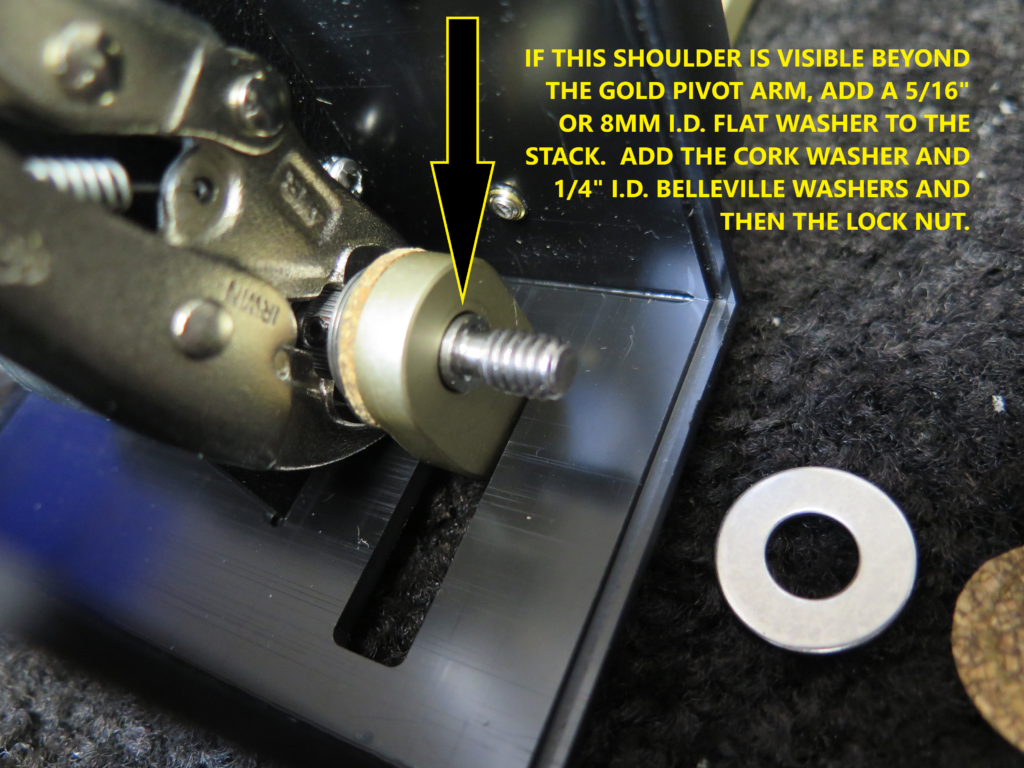

You’ll see the motor is attached to an internal wall with a modified shoulder screw and stack of Belleville washers. These spring washers are used to allow the arm to slip when someone grabs the lamp and physically tries to force the cover closed. Unfortunately they can also allow the arm to slip during an open or close operation which leads to that dreaded “TIMED OUT” message. Optec have redesigned the stack a bit to eliminate this issue going forward.

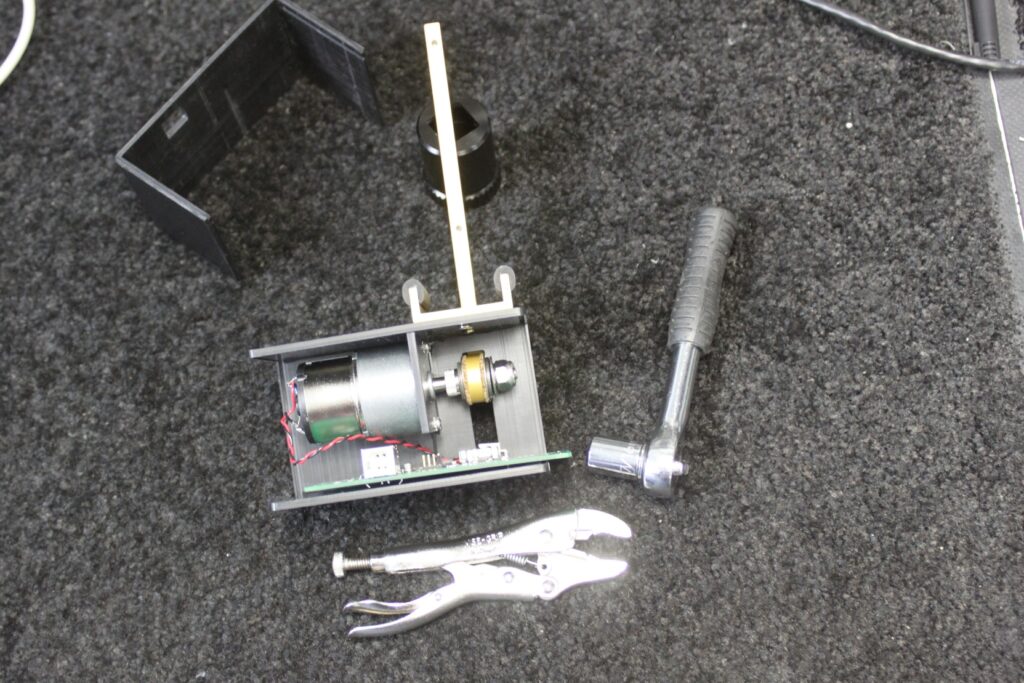

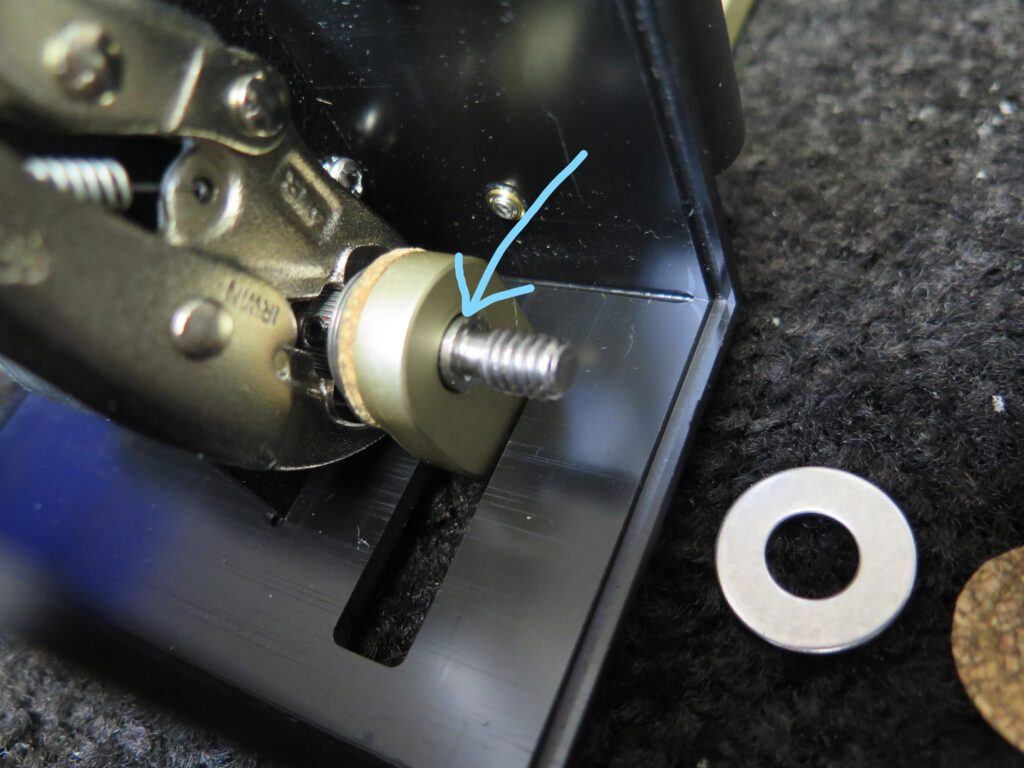

To correct, you might be able to adjust the washer stack by removing the lock nut and sliding off the washer stack to the pivot arm. Check carefully to see if the shoulder screw protrudes beyond the pivot arm. If so, rather than installing the cork washer next, install a 5/16” ID washer first to cover the exposed shoulder. Next add the cork washer and stack of Belleville washers. Finally screw the lock nut back in place and tighten while holding the shoulder screw near the motor (this is important to avoid breaking the internal motor gears).

In the end I decided to courier the unit back to Optec for repair as I did not want to render my unit completely useless in case I made a mistake.

I’m extremely grateful to Jeff, Tina and the team at Optec for all there help, patience and understanding. I’m a very happy customer and the flip-flat will be rejoining the Esprit120 when the IMT relocation is complete at it’s new rural location. I can then do a Homer Simpson and annoy Dave with “Flap goes open, flap goes shut, flap goes open ……”