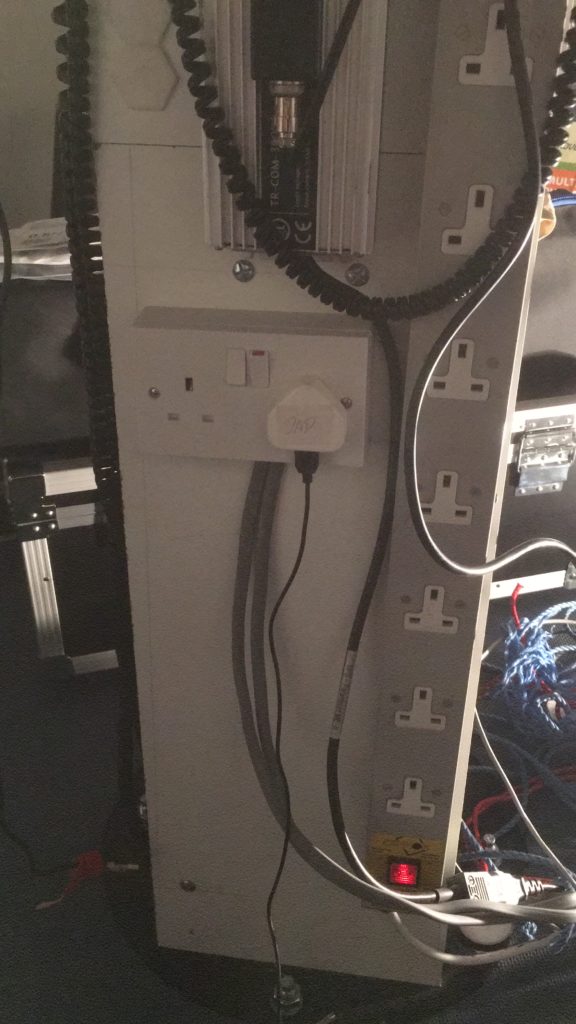

As the first phase of the build completes for the IMT3 observatory but before the commissioning stage begins, a few other additions need to be completed. We started with adding a UPS for the Intel NUC. The dome itself for the shutter at least runs on a battery backup in case of power failure, the dome automatically shuts. What we wanted to avoid was loosing power to the house and not being able to shut the PC down gracefully until power returned. The UPS also comes with software so that we can sense the power going and then ask the PC to shutdown if needed.

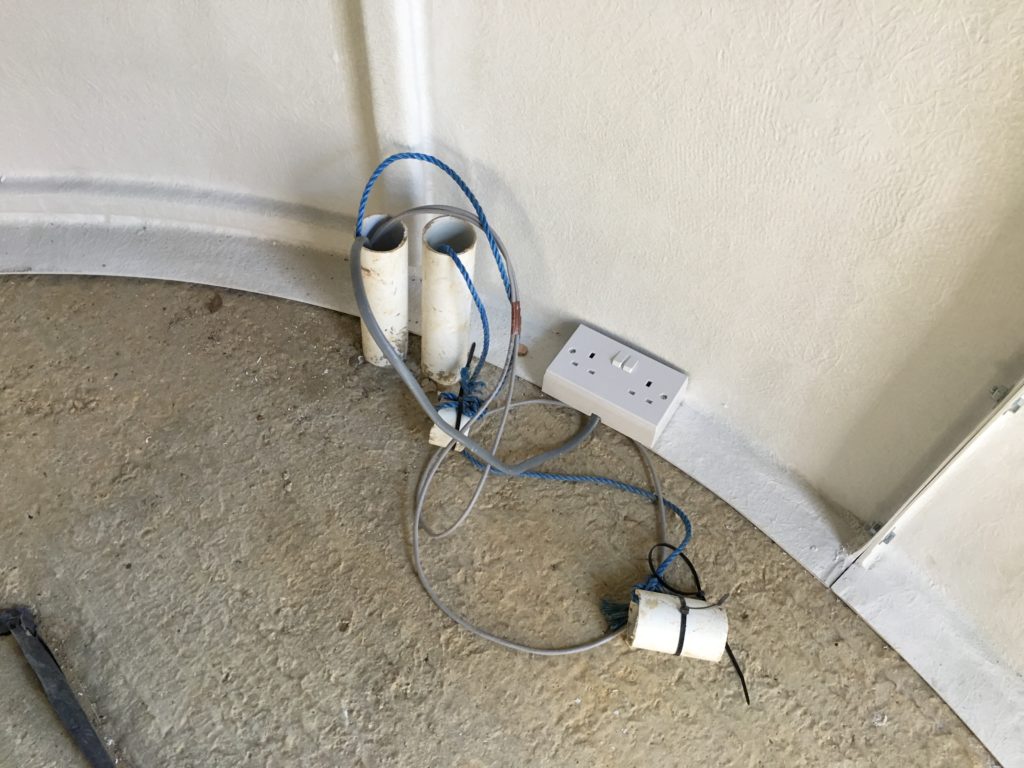

Temporary LED lighting has been fitted but needs properly fixing and connecting into the master switch and the soft switch for turning on and off remotely. The cables meanwhile to the first of many USB hubs starts to fill up.

An adapter station is fixed to the wall for the copious adapters one needs for astronomy

Shortly followed by another due the copious adapters needed for astronomy……….

Hat hooks are added due to a few unfortunate instance with a head and the mount which concluded in a hospital trip and some superglue.

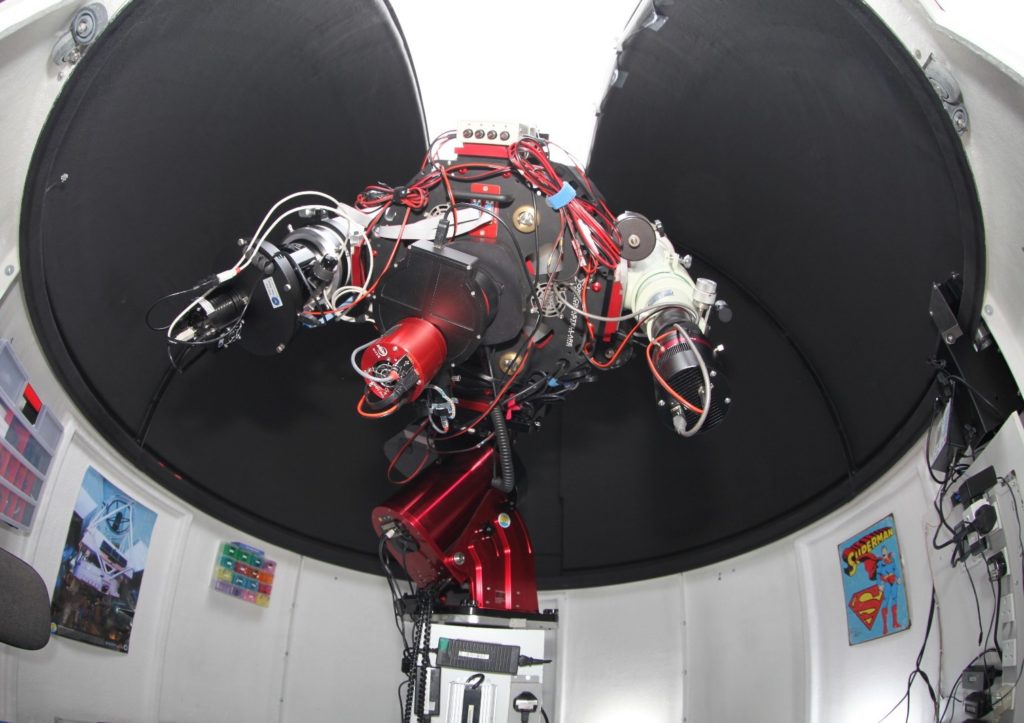

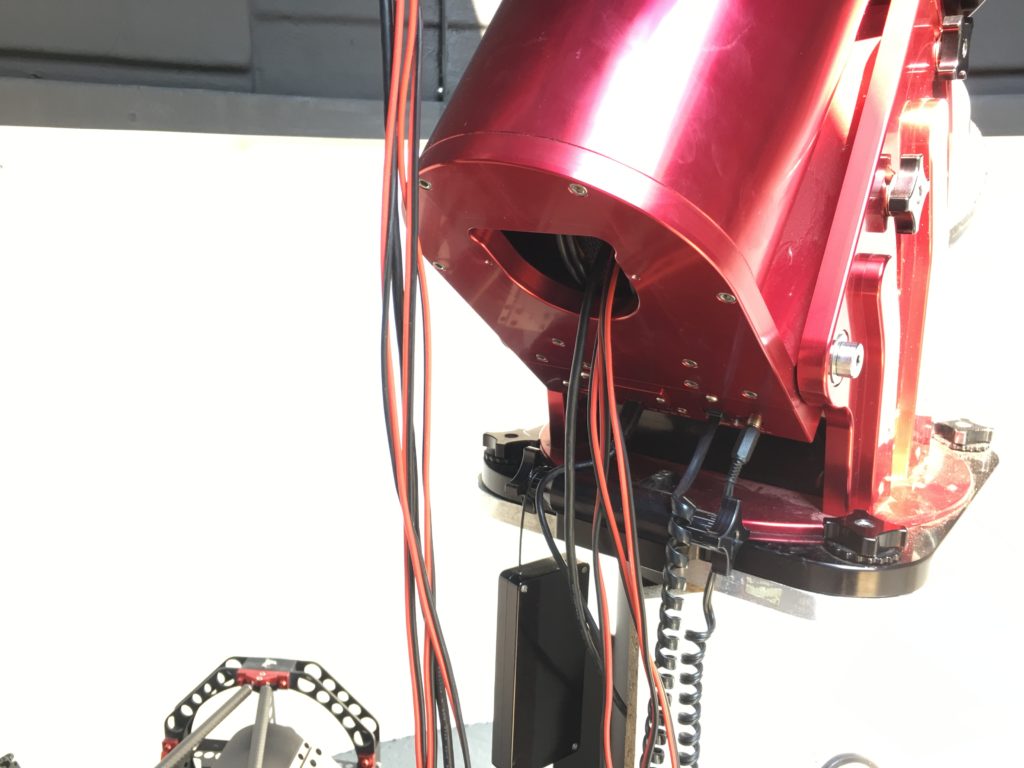

Multiple weights can be seen supporting the large amount of the wieght at the business end of the mount

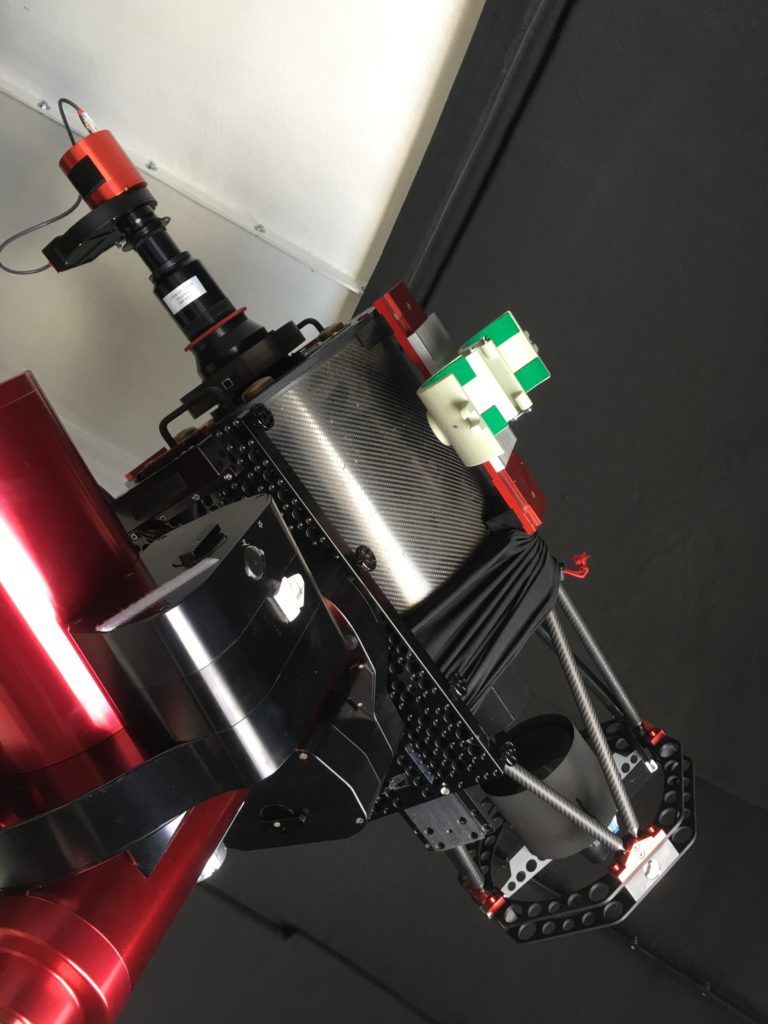

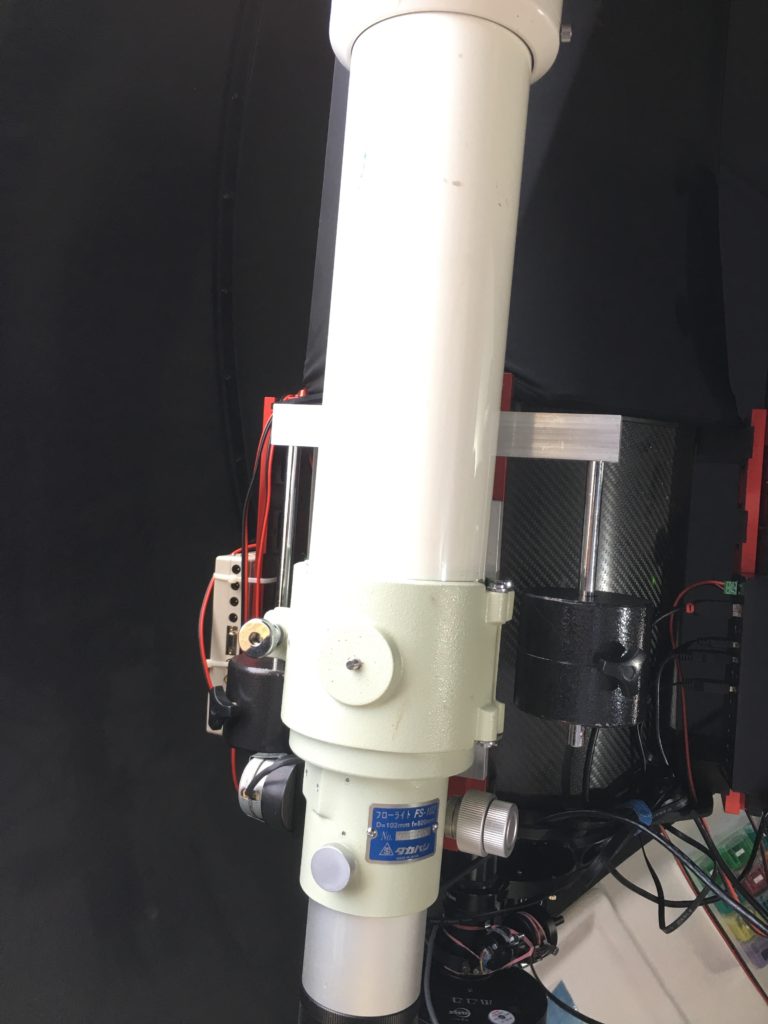

Whilst there is still much more to add including the imaging trains for the other OTAs and the focusers for each of them being added (Lakeside) I managed to go out one evening and get first light with the 12″ OTA on the Moon.

I started the first run of polar alignment with the PoleMaster for which I dedicated an entire blog entry to it here.

as it’s more complicated than one might think. This is the initial polar alignment through hard work and measuring twice always!

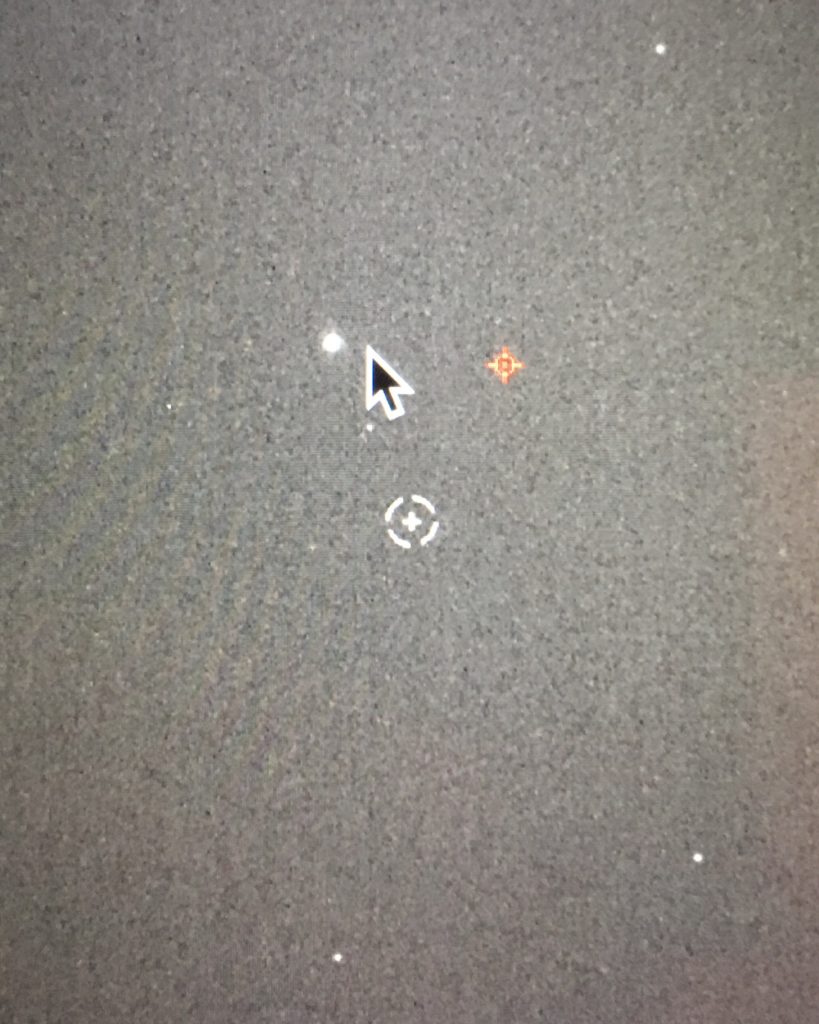

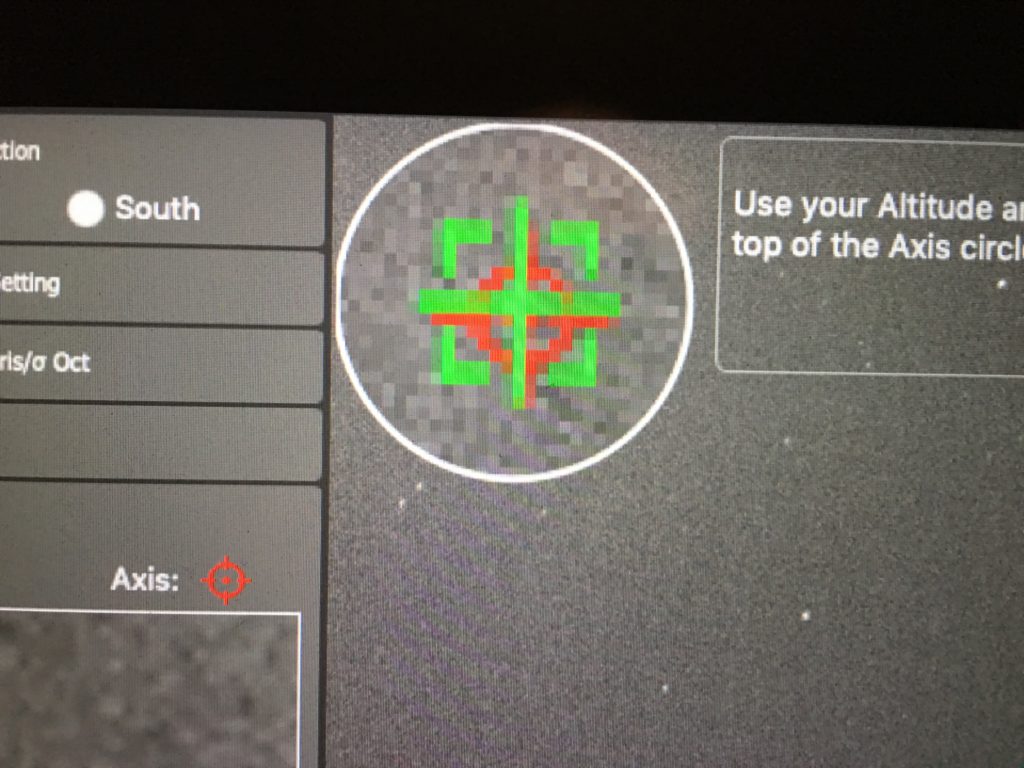

Polaris is the bright star and needs to be in the white circle. Not bad for a rough alignment. I then proceeded to adjust the alignment based on this first result until the green and red square/crosses aligned. It should be noted that the accuracy for the Polemaster is ok for short focal length OTAs but for long focal length you need to use a combination of approaches which include on the Paramount using TPoint followed by drift aligning using PHD2.

So after many days building out the IMT3 the 3 geeks with their hard hats relax and have another beer.

And the business end of the scope starts to look more useful and beautiful to the trained eye.